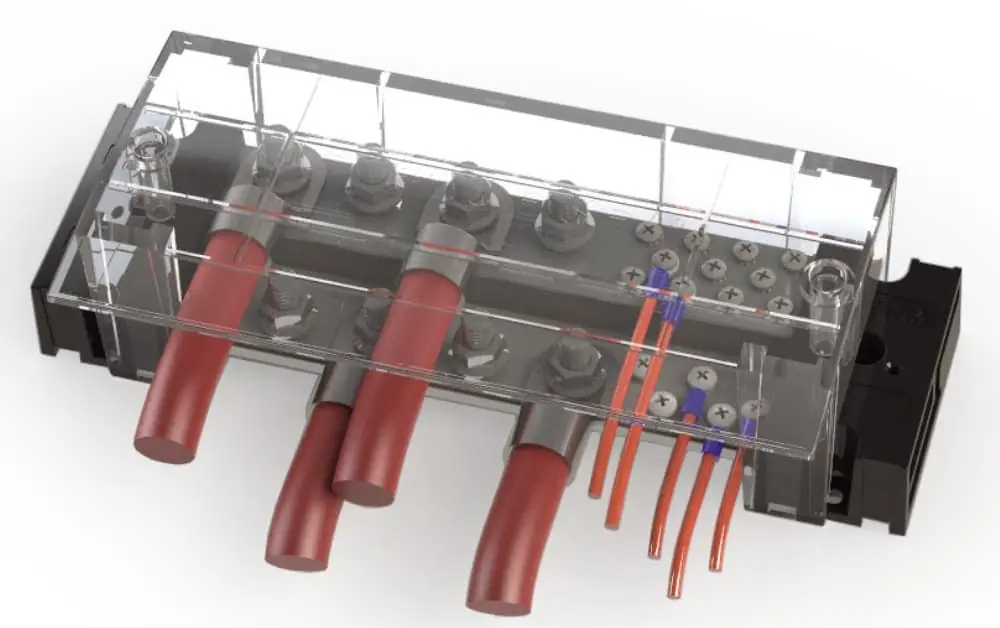

Tin plated 1000 Ampere copper busbar, used to consolidate large and small conductors in complex wiring systems. Ideal as a common ground point or for high amperage cables such as battery, bow thruster, windlass and electric winches.

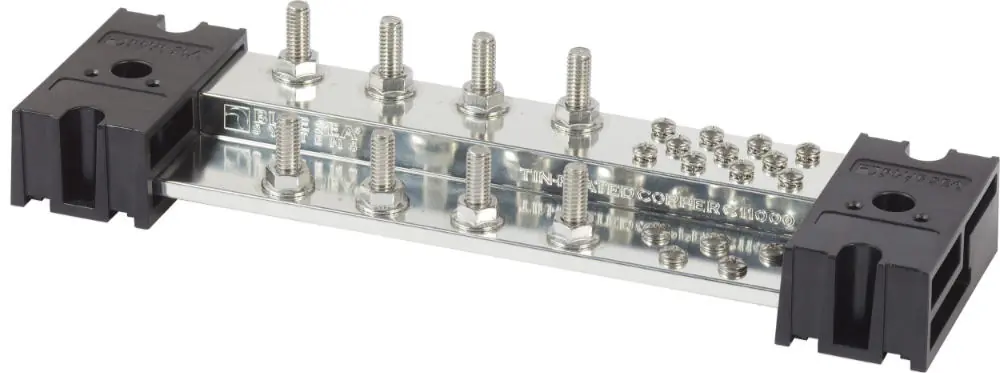

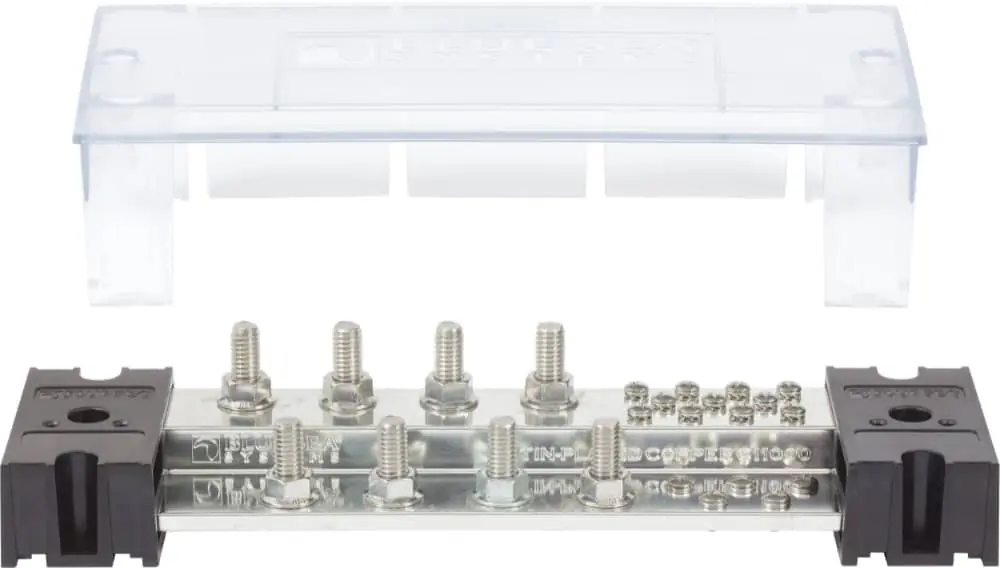

The unique stepped, raised bus design and stud spacing of the PowerBar allows multiple connections without interfering with the cables attached to the next stud. The step height is the same as comon fuse blocks which allows direct connection without connecting wires.

- 1,000 Amp busbar for large complex wiring systems

- Tin plated pure electrical copper for maximum conductivity

- Stepped bus design offers two elevations for conductors which doubles the density of the wire loom compared to traditional bus bars

- Busbar and fuse block elevations match common fuse blocks allowing for multiple fuse block attachment, eliminating the need for connecting cables

- One-piece serrated flange nuts ensure correct and secure connections

- Stainless steel 8-32 screws with captive lock washers for securing smaller gauge wires

- Busbar may be cut to a shorter length to accommodate constricted spaces

- Bi-directional busbar end caps allow the grouping of additional busbars

- Snap on insulating cover meets ABYC and USCG requirements and includes label recess

Available in two versions, with 3/8" studs or 5/16" studs.

See the Downloads Tab for detailed dimensional drawings.

Specifications:

| Model | 1990 | 1991 | 1992 | 1993 |

| Max. Voltage | 150V AC / 48V DC | |||

| N° of Studs x Size | 8 × 3/8"-16 | 12 × 3/8"-16 | 8 × 5/16"-18 | 12 × 5/16"-18 |

| N° of Screws x Size | 5 x #10-32 + 11 x #8-32 | |||

| Continuous Rating Ic | 1000A | |||

| Base Material | UL94-V0 Glass Reinforced Plastic | |||

| Bus Material | Tin Plated Copper CDA 110/UNS11000 | |||

| Mounting Holes | #10 (∼ M5) Screws | |||

| Recommended Stud Torque | 140 in-lb (15.82 Nm) | |||

| Weight | 2.8 kg | |||